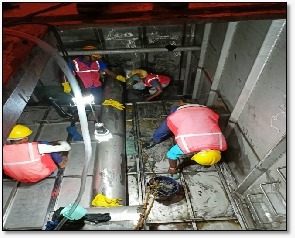

We have a wealth of knowledge and experience in providing tank cleaning solutions and other chemical

cleaning services like Plate & Tube type heat exchanger, Au & Oil coolers, Dynamo & Cooling Tower.

Correct tank maintenance and cleaning will help you avoid many issues, like moisture building up

inside and corroding the tank, causing leaks; or sludge collecting at the bottom of the tank, which

can contaminate contents and clog pipelines. Harmful mould, bacteria and microbes can grow inside

tanks that have not been cleaned for a long time, which could also lead to contamination, blockages

or damage being done to filters. Many of these issues can be extremely costly to rectify, if left

unchecked for long periods of time, so it’s essential to adhere to your maintenance schedule.

Crews in charge of cleaning should have daily meetings on-site, to run through any safety concerns

and potential complications that might be encountered during the cleaning operation. All discussions

need to be fully documented, and a Health & Safety Plan should be drawn up, before any work

commences. Having a regular tank cleaning and maintenance schedule will not only keep you compliant

with licensing obligations, it will almost certainly save you money in the long run. Visit our tank

cleaning page to learn more about SA-Engineering tank cleaning services. Alternatively, if you would

like help planning a fuel tank cleaning and maintenance schedule, or have any other questions,

please contact us today.